Alu-Power HPC Carbide End Mills

For Truly High Performance Machining

Aluminum, Non- Ferrous & Non Metallic Materials

Oustanding Performance with ALL levels of CNC Machines

Requires LESS horsepower

Delivers BETTER surface finishes

Provides LONGER tool life

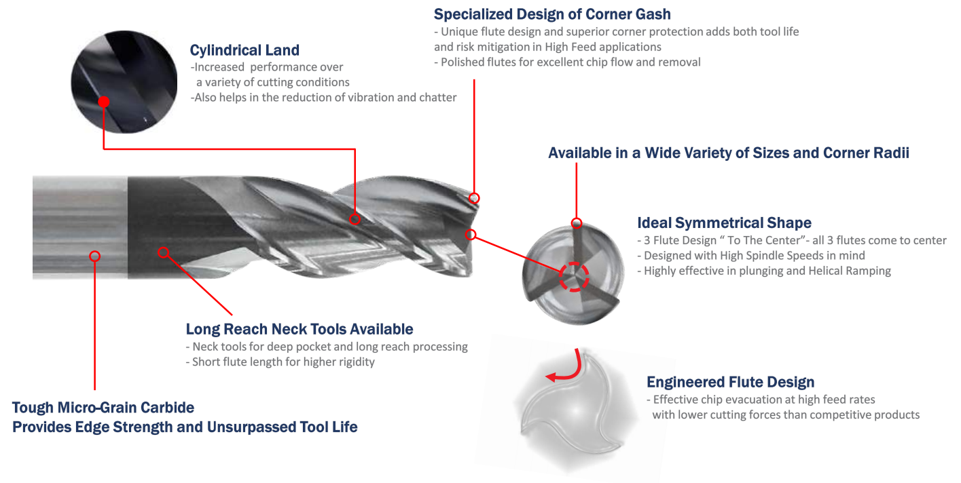

- 3 Flute, 37° Helix

- Balanced by Design

- Cut-to-Center” – all 3 flutes

- Cylindrical Land

- Proprietary Corner Gash

- Tough Micrograin Substrate

- Balanced by Design

- Cut-to-Center” – all 3 flutes

- Cylindrical Land

- Proprietary Corner Gash

- Tough Micrograin Substrate

Will Run at MAXIMUM

Machine Speed

When Ordering, Be Sure to Say “HPC”

Select by part #, by diameter,

by LOC, or OAL, even by radius

When horsepower is limited

Use Alu-Power

Conventional Design

2 & 3 Flute

Universal Excellence in ALL Operations

Roughing, Finishing, Plunging, Ramping, Pocketing, Circular Interpolation, Thin and Long Wall Applications

Delivers very good floor and wall finishes

Provides efficient chip evaculation

Runs at higher feed rates and produces lower cutting forces

The Widest Range of Standard Sizes

Cutting Diameters from 1/8” thru 1”

Stub, Reg, Long & X-Long Flute Lengths

Multiple Choices of Reach Lengths

Many Radius Choices

Stub, Reg, Long & X-Long Flute Lengths

Multiple Choices of Reach Lengths

Many Radius Choices

.010, .015, .030, .060, .090, .125, .190, .250

IN STOCK

Your choice – Coated or Non-Coated

STANDARD

Series E5G - Non-Coated

Series JAG - DLC-Coated

6061, 7050 & 7075 don’t usually need coated tools. Aluminum Lithium & Silicon Alluminum need coating for more abrasion resistance. Competition mostly provides TiCN, or ZrN. We provide DLC-Coating as standard, delivering far superior tool life.

Perfect on Low-Power Machines

(i.e., Haas VF2, Haas Osprey, Okuma 15K RPM)

On low power machines, 3 flute tools will provide higher metal removal rates (MRR) than 2 flute tools, but require higher horsepower

Perfect on High-Power Machines

(i.e., Makino MAG 120kw (160hp), Mitsui Seiki, Starag Blisk)

On high power machines, 3 flute tools provide optimal performance in heavy, roughing cuts

- Slotting Ap (radial) - 100% Ae (axial) - 70-100%

- Profiling Ap (radial) - 150-200% Ae (axial) - 30-60%

Coming Soon

Alu-Power HPC - 2 Flute

For use on low power machines and pulling less horsepower

Finished Part

V7PlusA Cover